|

Dismantling the locomotive |

|

|

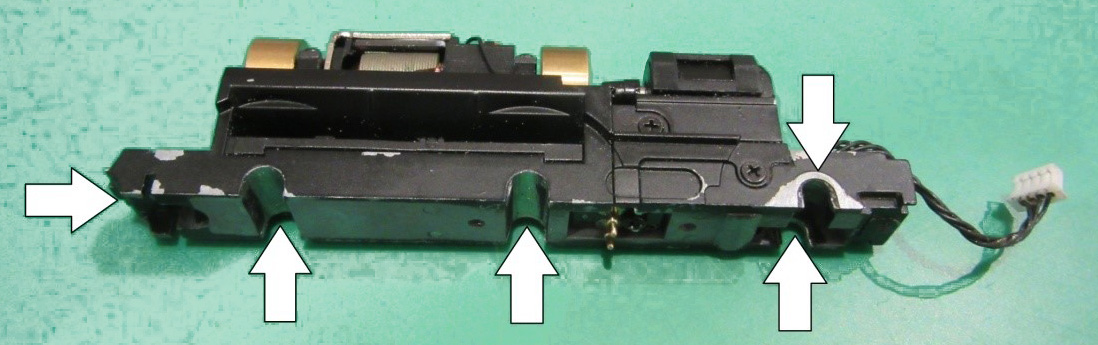

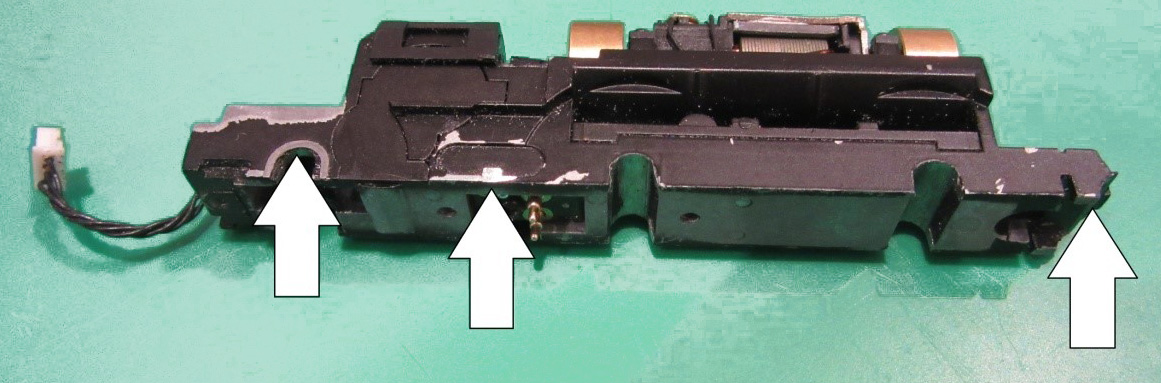

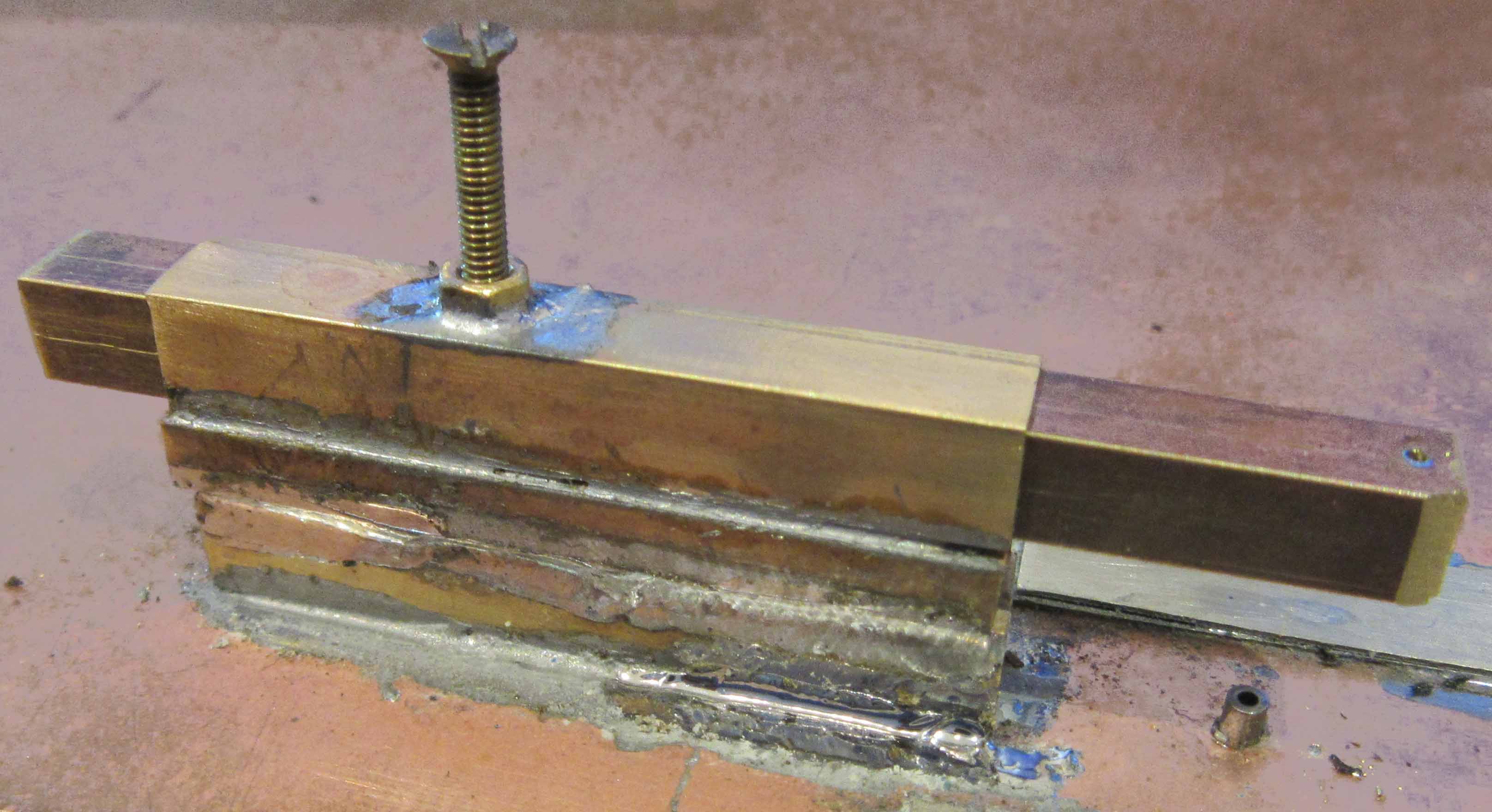

Unplug the plastic plug connecting the cables from the locomotive to the tender. This cabling will be used in future so be careful not to deform it. Unscrew the bolt on the locomotive which holds the locomotive to the tender drawbar. This is a special bolt with a waist so be extra careful not to lose it. Unscrew the front and two middle Philips screws in the plastic keeper plate. Pull the chassis block down from the front (there is a tab at the rear which holds it in place). The keeper plate should come away from the main chassis block. While the wheels and coupling rods are not required, the final drive gear is needed. Remove the wire which represents the sanding gear. Hold the rear axle in a pair of pliers and remove the wheels with a twisting motion, slide off the brass bushes (they can be very tight). Place the axle with the centre gear in a vice so that the gear wheel is supported on the vice sides but the axle is loose, tap the axle with a small hammer or similar and the gear wheel will slide off the axle. If you do not have a vice use a pair of pliers on one side of the gear wheel, gently slide the plastic gear down and off the axle by holding the axle vertical and pressing down. It is very important not to damage this gear. You will now have a box of bits and an invalid Hornby guarantee! |

|